|

||||||

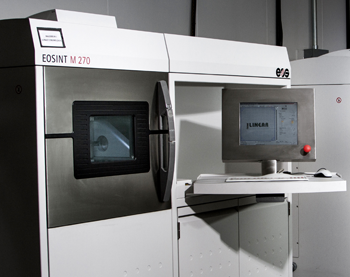

DMLS/DMLM Equipment Profile

DMLS/DMLM 3D Metal Printing Machines

Four (4) EOS M 270

The EOSINT M 270 is an additive layer manufacturing system for metal components. It builds high quality metal parts from 3D CAD data fully automatically, with no need for tools. The system builds parts up layer by layer by melting fine metal powder with a laser, enabling the creation of extremely complex geometries. Parts can be made that wouldn't be possible with CNC machining, including deep grooves and three-dimensional cooling channels. Innovative companies are using this technology for fast, flexible, cost-effective prototypes, series production parts or even spare parts.

Nitrogen Environment - 9" x 9" x 7"

Materials Available: Inconel 625, Inconel 718, cobalt chrome (CoCr), maraging steel (MS1) and 5-5/17-4/316 Stainless Steels.

One (1) EOS M 280

The EOSINT M 280 produces top-quality metal parts direct from three-dimensional CAD data, fully automatically, in only a few hours and without tools. The DMLS/DMLM process builds the parts layer by layer, melting fine metal powder with a laser to create extremely complex geometries such as freeform surfaces, hollow sections and articulated moving parts. The EOSINT M 280 is an updated and improved version of the EOSINT M 270.

Argon Environment - 9" x 9" x 12"

Materials Available: 15-5/17-4/316 Stainless Steels, Aluminum (AlSi10Mg), Cobalt Chrome, Inconel 625/718, Maraging Steel (MS1), Titanium (Ti64)

One (1) SLM 280

The SLM 280HL machine is for users interested in additive high-speed production of large parts. Manufacturing speed is 30 CC/h and fused metal powder layers have a thickness of 20-100 µm. Equipped with a fibre laser whose power can go up to 1000 W, it is implementing an original technology. Dual-beam laser and the special optics improve the quality of the manufactured parts. The machine is equipped with the patented devices that are installed on the line SLM : security filter, protection gas recirculation system, bi-directional loading device... A wide range of metals can be treated (Stainless Steel, Steel Tools, Cobalt-Chromium, Aluminum, Titanium...), which meets varied applications.

Argon Environment - 11" x 11" x 14"

Materials Currently Available: Aluminum (AlSi10Mg), Titanium (Ti 64)