|

||||||

Off Shore Manufacturing for Metals

3Axis Development has been known for high quality prototypes and Short-Run volumes for its customer base for almost 20 years. In an effort to react to client requests we have established a relationship with a manufacturing company based in the US with its own offshore resources for metal production in many categories.

The uniqueness of their program is that while you may have perceived production quantities you do not need to fill a full container to place an order. This allows you to schedule faster and save on shipping by Air.

Our team specializes in castings and stampings for over 40 years. Our engineering team can provide you with support from original development to full run production quantities.

Our team provides Off Shore Metal Manufacturing Services in many targeted industries:

- Engine Components

- Furniture (Indoor and outdoor)

- Industrial and Safety Railing Products

- Hospitality Industry Parts

- Home Building and Construction Industry Parts

- Outdoor and Garden Products

- Outdoor Lighting and Signage Products

- Window and Door hardware

|

Sand Casting – Aluminum / IronTooling for Sand-cast parts is generally lower in cost. We offer services for aluminum, iron alloys and white bronze for lower volume parts. The process can sometimes deliver a more porous casting.

|

|

Gravity Casting /Permanent Mold Casting – AluminumWhere sand castings are derived from a pattern press process, permanent mold tooling provide better dimensional consistency with less porosity than sand castings. Aluminum gravity castings: A319/A356 and A535 Almag |

|

Die-Casting – Aluminum, Zinc, BrassDie-casting is utilized for high volume deliverables in aluminum, zinc and brass. This high pressure molding process offers a higher precision part, with excellent surface quality and strong dimensional accuracy 2% of actual design dimension) . Die-cast parts require little machining straight from the tool. Usually reflects higher tooling costs as it requires high compression tooling that can withstand the heat of molten metal.

|

|

Investment Casting – steel, stainless steel, white bronzeThe lost wax process offers a pathway to intricate shapes with high-precision accuracy. Investment cast parts from tooled wax require less machining except for certain flatness or tapped or reamed holes.

|

|

Stampings, Forming, Extrusions and FabricationsSheet metal forming is utilized to structure metal into specific shapes and sizes. The common techniques include bending and forming, rolling, stamping, punching and welding. Additional capabilities include deep draw stamping and cold headed forging. Specific materials/alloys available upon request. 6061/6063 sheet and extrusion (only if the extrusion is fabricated, not just shapes)

|

|

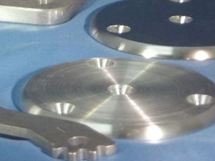

MachiningWe employ machining techniques including, but not limited to, CNC machining (for high precision), drilling, tapping, turning and grinding as needed. Specific materials/alloys available upon request. |

|

AssembliesFull assembly processes are controlled for high production programs at our factory facilities. |

Metal Machined PrototypingWe can produce CNC machined metal aluminum prototypes based upon your engineering/CAD drawings. |

Materials: Aluminum, Brass, Cast Iron. Malleable Iron, Ductile Iron, Plastic, Stainless Steel, White Bronze and Zinc

Finishes: Anodized, Chromate Conversion Coating, Dacromet, Galvanized, Mill, Plating, Polishing and Power Coating

Don't see it here?

In addition to the above processes, our team can provide custom manufactured products using fiberglass tubing, puncture resistant material, silicon, etc. We encourage you to reach out to us with your product requirements.

We provide Off Shore Metal Manufacturing Services to many industries including:

- Industrial and Safety Railing Products

- Engine Components

- Window and Door Hardware

- Furniture (indoor and outdoor)

- Outdoor Amenities Manufacturers

- Outdoor Lighting and Signage

- Home Builders and Construction Companies

- Hospitality Companies

- Waste Management Companies

Need more information about our Metal Polishing Services?

Please contact us at (561) 752-9095. Our highly skilled team of engineers and design technicians are ready to take on your most demanding Metal Polishing Services projects from our prototyping services menu.